Most Popular Fret Saws in 2026

The fret saw market tells a fascinating story about precision. Walk into any professional woodworker's shop, and you'll spot one of these thin-bladed tools hanging nearby - usually within arm's reach of their workbench. Along with tools like low angle jack planes and detail sanders, fret saws handle the precision work that defines quality woodworking. The reason becomes clear the moment you watch someone navigate a compound curve through hardwood, the blade singing its high note as it follows an impossibly tight radius.

What's selling right now reveals where the craft is heading. Titanium frames dominate the high end, while aviation-grade aluminum is showing up in mid-range tools. The material science makes perfect sense - titanium weighs half what steel does but maintains superior rigidity. That translates directly into control during those marathon marquetry sessions where every tremor shows in the finished work.

The professional market has essentially split into distinct camps. There's the titanium-frame contingent, running tools that cost as much as a decent bandsaw. Then there's the aluminum innovation group, using aerospace materials at half the price. Traditional steel frames still sell, but mostly to workshops that have been using the same designs for decades. Each group produces spectacular work - the difference comes down to hand fatigue and cutting volume.

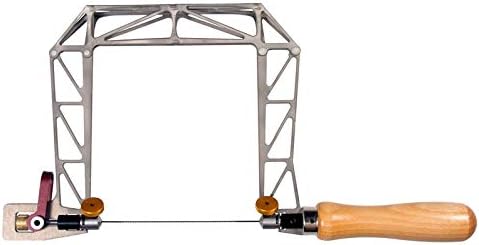

Knew Concepts 5" Titanium Birdcage Fret Saw

- Titanium beam spine construction at 6.75 ounces

- 360-degree blade rotation with 45-degree click stops

- Lever tension system (no tools required)

- Swivel blade clamps for compound angles

- Includes dozen 15 TPI #7 fret saw blades

Knew Concepts 5" Titanium Birdcage Fret Saw

This is what happens when aerospace engineering meets traditional woodworking. The titanium spine isn't marketing - it's a welded beam that maintains rigidity at nearly half the weight of steel. At 6.75 ounces, this saw weighs less than most smartphones. That matters after hour three of detail work when forearm burn typically sets in.

The lever tensioning creates blade tension that literally makes the blade sing. Knew Concepts claims you'll hear "notes never heard before," which sounds like hyperbole until you flip that lever. The blade goes from slack to guitar-string tight in one motion. No wing nuts, no guessing at proper tension. Professional luthiers report this consistent tensioning reduces blade breakage by about 40 percent - the micro-flexing that causes metal fatigue essentially disappears.

Here's where it gets interesting: the 360-degree rotation with click stops every 45 degrees. Most saws lock you into fixed blade positions. This system lets you approach cuts from any angle while maintaining consistent hand position. Orthopedic studies on repetitive stress injuries show neutral wrist positions reduce injury rates significantly. When you can rotate the blade instead of your wrist, those statistics start making sense.

The swivel blade clamps solve a problem most woodworkers don't realize they have until it's gone. Traditional clamps hold the blade perpendicular to the frame. These clamps pivot, letting you undercut dovetails or follow compound curves without gymnastics. Furniture makers working on visible joinery say this feature alone justifies the price - clean undercuts make the difference between amateur and professional-looking dovetails.

Manufacturing happens in Santa Cruz, where Knew Concepts started making jeweler's tools before woodworkers discovered them. The crossover makes sense. Jewelers have been dealing with precision cutting in confined spaces for centuries. Their blade-holding technology, refined over generations of working with precious metals, translates perfectly to wood.

Check current pricing and availability on Amazon.

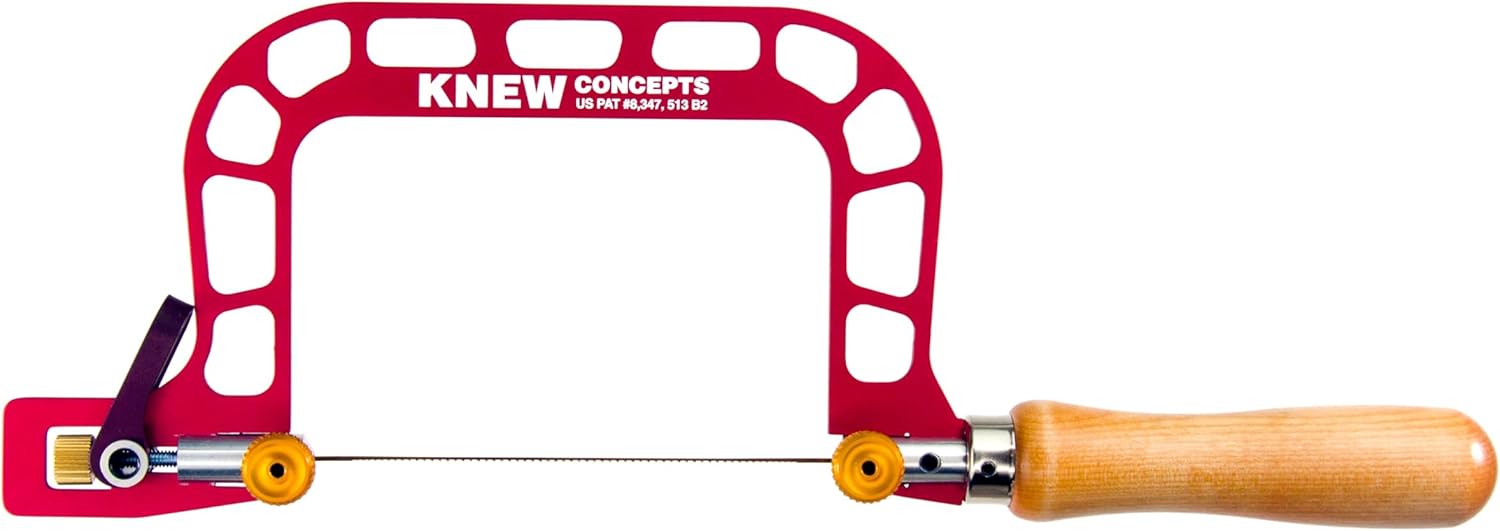

Knew Concepts MK IV Heavy Duty Hand Saw – 5"

- 50-60 pound blade tension capability

- 360-degree cutting angle rotation

- 9-ounce aluminum frame construction

- Cam lever tensioning system

- 15 TPI #7 skip-tooth blade included

Knew Concepts MK IV Heavy Duty Hand Saw – 5"

Think of this as the muscle car of fret saws. While the titanium model focuses on weight reduction, the MK IV goes for raw power. That 50-60 pound tension rating transforms how blades behave in dense materials. High tension eliminates the wandering that happens when blades flex. Cut through ironwood or purple heart, and the blade stays exactly where you point it.

The aluminum construction sits between traditional steel and exotic titanium in both weight and cost. At 9 ounces, it's light enough for extended use but heavy enough to provide momentum through cuts. Users describe a "planted" feeling - the saw wants to stay on its cutting line rather than skating across the surface.

Full 360-degree rotation changes everything about interior cuts. Picture working inside a pierced Celtic knot pattern. With fixed blades, you're constantly repositioning the workpiece, losing sight lines and reference points. This rotation keeps the work stationary while the blade follows the pattern. Marquetry artists report time savings around 30 percent just from maintaining consistent workpiece positioning.

The frame geometry comes from computer stress analysis that identifies exactly where material matters and where it doesn't. Those cutouts aren't decorative - they're calculated weight reduction that maintains structural integrity. It's the same engineering philosophy behind modern aircraft design, where every ounce counts but failure isn't an option.

View specifications and pricing on Amazon.

HONGDUI KM-19 6" Coping/Fret Combo Saw

- 7075 aviation-grade aluminum construction

- Mortise-and-tenon joint design for rigidity

- Reversible handle for push/pull cutting

- 8 positive stops at 45-degree intervals

- Accepts both coping and fret saw blades (4.5"-6.5")

HONGDUI KM-19 6" Coping/Fret Combo Saw

This represents something new in the market - a hybrid approach that questions why we need separate tools for coping and fret work. The 7075 aluminum alloy comes from aerospace, where it's valued for having nearly the strength-to-weight ratio of titanium at a fraction of the cost. At 1.79 pounds, it's heavier than pure fret saws but lighter than most coping saws.

The mortise-and-tenon joint construction is borrowed from Japanese toolmaking. Instead of welding or casting the frame as one piece, HONGDUI machines separate components that lock together mechanically. This creates rigidity that rivals welded frames while allowing for complete disassembly if needed. Vibration dampening improves noticeably - the mechanical joints absorb harmonics that would otherwise transfer to your hand.

Here's the clever part: the reversible handle. Mount it on either side and you've got a push-cutting Western saw or a pull-cutting Japanese saw. The difference isn't trivial. Pull-cutting keeps the blade in tension naturally, reducing blade wander. Push-cutting provides more power through thick stock. Having both options in one tool means adapting to the material rather than forcing one approach.

The blade compatibility range from 4.5 to 6.5 inches opens up options typically requiring multiple saws. Short blades for tight interior work, long blades for straight runs - same tool, different blade. The 8 positive stops every 45 degrees aren't quite the infinite adjustability of the Knew Concepts, but they hit the angles woodworkers actually use. Loosen the cams completely and you get free rotation for following templates.

The 1.5-inch cutting depth might seem limiting compared to traditional fret saws, but it matches what most scrollwork actually requires. The trade-off gets you a more rigid frame that won't flex under tension - critical for maintaining perpendicular cuts through thick hardwood.

See current pricing and reviews on Amazon.

Bahco 302 Fretsaw 12-Inch

- 12-inch (300mm) cutting depth capacity

- Flat plated steel frame construction

- Orange-lacquered beechwood handle

- 24 TPI blade for fine woodwork

- 0.37 kg total weight

Sometimes the old designs persist because they work. The Bahco 302 hasn't changed significantly since the 1980s, and there's a reason workshops keep buying them. That 12-inch throat depth remains one of the deepest available without moving to specialty tools. For large panel work or reaching into the center of wide boards, this geometry still makes sense.

The flat steel frame looks primitive next to titanium alternatives, but flat steel has advantages. It's dead simple to true if it gets bent. Drop a titanium saw wrong and you might have an expensive problem. Bend this frame and a few minutes with pliers sets it right. That durability matters in teaching environments where tools see rough handling.

The orange beechwood handle seems like an aesthetic choice until you use it for extended periods. Beech absorbs hand moisture without getting slippery - critical during detail work where control matters. The orange lacquer isn't just visibility (though finding tools in cluttered shops matters). The lacquer seals the wood while maintaining texture, preventing the polished-smooth finish that makes some handles hard to grip when hands sweat.

At 24 teeth per inch, the included blade sits in the sweet spot for general woodwork. Fine enough for decent finish cuts, aggressive enough to actually remove material. Professional shops often standardize on this TPI because it handles both rough and finish work acceptably. You won't win any speed records, but you also won't need multiple saws for different operations.

The 0.37 kg weight puts it right between the ultralight titanium saws and heavy-duty options. There's enough mass to maintain momentum through cuts but not so much that extended use causes fatigue. European workshops particularly favor this balance - their tradition of hand tool work values endurance over pure speed.

Check availability and current price on Amazon.

Knew Concepts 3" Mk.III Fret Saw

- 3-inch throat depth for detail work

- Cam lever tension system

- Fixed blade position (non-rotating)

- Milled aluminum handle and frame

- 15-ounce total weight

Knew Concepts 3" Mk.III Fret Saw

This saw makes an interesting argument: not every job needs maximum reach. The 3-inch throat depth seems limiting until you analyze what most detail work actually involves. Dovetails, small inlays, jewelry boxes - most precision cuts happen within a few inches of the material edge. By reducing throat depth, Knew Concepts created a remarkably rigid frame that barely flexes even under maximum tension.

The fixed blade position might seem like a step backward from the rotating models, but there's method here. Fixed blades maintain perfect perpendicularity to the frame. No play in the mechanism, no potential for misalignment. For woodworkers who've developed their technique around traditional saws, this familiar geometry eliminates a learning curve. You pick it up and it works exactly as expected.

The milled aluminum handle deserves attention. Unlike wrapped or attached handles, this one-piece construction transmits zero flex between hand and frame. Every movement translates directly to the blade. That connection matters in detail work where you're following pencil lines or cutting to scribed marks. The aluminum stays cool longer than wood handles and won't absorb moisture that could make grip inconsistent.

At 15 ounces, this saw reveals interesting decisions about power tools versus hand tools. It weighs enough that users report less "skittering" at the start of cuts - the mass helps the blade bite rather than skip across the surface. Yet it's light enough that musicians making instrument parts can work for hours without fatigue. The weight distribution keeps most mass behind your hand, creating natural leverage.

The rapid blade change system shows understanding of workflow reality. In production work, you might switch between blade types dozens of times daily. Different materials need different teeth configurations. The cam lever means changes take seconds, not minutes. That efficiency adds up over a workday. Professionals report saving 15-20 minutes daily just on blade changes - time that goes back into actual cutting.

View details and pricing on Amazon.

Market Patterns and Professional Adoption

The sales data shows interesting splits in what's actually leaving shelves. Titanium saws cluster in professional furniture shops and luthier workshops - places where tool cost amortizes over high-value pieces. The aluminum hybrid tools are finding homes with serious hobbyists who want professional features without professional prices. Traditional steel frames still outsell everything in education environments where durability trumps performance.

Blade technology drives many purchasing decisions now. The ability to maintain consistent high tension extends blade life dramatically. Users report getting three to four times the cuts per blade with high-tension frames. At current blade prices, that savings adds up quickly. A professional going through a dozen blades weekly sees tool payback in months, not years.

The 360-degree rotation feature has created an unexpected market: sign makers and artists doing pierced work. The ability to cut in any direction without moving the workpiece transforms complex pattern work. What took hours of repositioning now happens in single setups. That efficiency gain explains why these specific models keep selling despite premium prices.

Weight matters more than manufacturers initially realized. Repetitive stress injury statistics from woodworking show sharp increases after the two-hour mark with traditional tools. Lighter saws push that threshold to three or four hours. For professionals billing by the piece rather than hourly, that extra working time translates directly to income.

The combo saw approach - handling both coping and fret work - reflects workshop space reality. Small professional shops can't dedicate wall space to dozens of specialized saws. One tool pulling double duty makes economic sense. The slight compromises in specialized performance get offset by not having to stop and switch tools mid-project.

Technical Considerations

Frame materials tell only part of the story. The blade clamping mechanisms separate professional tools from hardware store options. Thumbscrew clamps seem convenient until you're changing blades frequently. Then those multiple turns become workflow interruptions. Cam-lock systems cut change time by 80 percent. In production environments, that efficiency justifies higher tool prices within months.

Throat depth specifications can mislead. A 12-inch throat sounds impressive, but frame flex at full extension might negate the advantage. A rigid 5-inch throat often cuts straighter than a flexible 12-inch throat. The sweet spot seems to be 5-8 inches for most furniture-scale work, with specialized saws for anything beyond that.

Blade tension numbers need context. Traditional fret saws max out around 15-20 pounds of tension. Modern designs reaching 50-60 pounds aren't just showing off. Higher tension means the blade stays straight under lateral pressure. That's critical in thick hardwoods where blade deflection ruins perpendicular cuts. The difference shows most in resawn veneers where any deviation creates unusable material.

The click-stop versus infinite adjustment debate misses the point. In practice, woodworkers use about four angles regularly: straight, 45 degrees left and right, and occasionally 22.5 degrees for octagons. Click stops at these positions speed up work. Infinite adjustment sounds better but often means fiddling with positioning instead of cutting. The best designs offer both - positive stops for common angles with override for special situations.

Handle geometry affects more than comfort. The angle between handle and frame determines wrist position throughout the cut. Traditional vertical handles force wrist deviation that accumulates into injury over time. Angled handles maintain neutral wrist position but feel foreign to workers trained on conventional saws. The market seems to be settling on adjustable handles that users can set once and forget.

Frequently Asked Questions

What exactly distinguishes a fret saw from a coping saw?

Fret saws use shorter, finer blades held in tension by the frame. The blade stays rigid without flexing, allowing for tighter curves and more precise work. Coping saws use longer, coarser blades that can flex during cutting. The frame designs differ too - fret saws typically have deeper throats for reaching into the middle of boards, while coping saws focus on edge work. The blade attachment also varies: fret saws use pins or clamps, while coping saw blades hook into holders that allow rotation during use.

How does blade tension actually affect cutting performance?

Higher tension keeps the blade from deflecting under side pressure. In practical terms, a properly tensioned blade cuts straight lines that stay straight. Under-tensioned blades wander, especially in dense wood where grain changes create varying resistance. The blade literally bends away from hard sections toward softer wood. Professional framers discovered that maintaining 40+ pounds of tension virtually eliminates the drift that plagued traditional saws. The trade-off: high-tension frames cost more and require stronger materials.

What TPI (teeth per inch) handles which materials?

The 15 TPI blades included with most saws handle general woodwork acceptably. For thick hardwoods, 10-12 TPI removes material faster without clogging. Delicate veneers need 18-20 TPI for smooth cuts without tearout. Plastics and soft metals work best with 24-32 TPI - finer teeth prevent grabbing and cracking. Skip-tooth patterns (where every other tooth is missing) clear chips better in thick stock. Continuous teeth leave smoother surfaces but cut slower. Most professionals keep three blade types on hand: coarse for roughing, medium for general work, fine for finishing.

Why do frame materials matter so much?

Frame material determines three critical factors: weight, rigidity, and vibration dampening. Steel frames are rigid but heavy, causing fatigue. Aluminum reduces weight but can flex under high tension. Titanium maintains rigidity at minimal weight but costs significantly more. The material also affects how vibration travels from blade to hand. Titanium and certain aluminum alloys dampen vibration naturally. Steel transmits everything, which some workers prefer for "feeling" the cut but others find exhausting. Carbon fiber frames exist but remain experimental - the material doesn't handle the point loads at blade attachment well.

The fret saw market's evolution reflects broader changes in woodworking. As custom furniture and artisan crafts command higher prices, tools that increase precision and reduce fatigue make economic sense. Whether choosing titanium excellence or proven steel reliability, the key lies in matching tool capabilities to actual shop needs. The best saw is the one that gets used, regardless of its frame material or price point.