Drill Bit Sharpeners That Actually Work in 2026

Picture this: You're drilling into wood, making decent progress, when suddenly - nothing. The bit's spinning, you're pushing harder, maybe even leaning your full weight into it. Still nothing. Just that awful high-pitched whine of metal refusing to bite.

Here's what's happening in that moment of frustration: the cutting edge of your drill bit has rounded over. What was once a precise angle of hardened steel, capable of slicing through material at the molecular level, has become a blunt instrument. The physics are unforgiving - a dull bit generates heat instead of cutting, which makes it duller still. It's a death spiral that ends with either a ruined bit or, if you're particularly stubborn, a burnt-out drill motor.

The drill bit sharpening industry emerged from this universal problem. And in 2025, after decades of refinement, we're looking at machines that range from $89 portable units to $800 professional systems. The question isn't whether sharpening works - it demonstrably does. The question is which approach makes sense for your particular situation.

The Economics of Sharp Bits

Let's start with the numbers that matter. A quality HSS (high-speed steel) drill bit runs between $3 and $15, depending on size. Cobalt bits cost more - typically $8 to $30. Carbide can hit $50 for a single bit.

Now consider this: testing by independent labs shows that a properly sharpened drill bit performs identically to a new one for the first 80% of its potential lifespan. Some tests, particularly those run by Tormek, suggest their four-facet sharpened bits actually outperform factory-new bits in both longevity and cutting efficiency.

The math becomes compelling quickly. If you're going through even 10 bits a month, that's potentially $150 in replacement costs. A mid-range sharpener pays for itself in two months. But here's where it gets interesting - the real cost isn't the bits themselves. It's the downtime, the trips to the hardware store, the project delays. Professional shops report that having on-site sharpening capability reduces drill-related delays by up to 70%.

How These Machines Actually Work

ApexscnView MR-13B: The Precision Angle Game

- 2-13mm capacity with 12 ER20 collets included

- 90° to 140° adjustable point angle

- 5300 RPM pure copper motor

- CBN wheel (pre-installed) plus SDC wheel included

- 110V corded electric power source

- Portable design with carry handle

The ApexscnView MR-13B represents what happens when Chinese manufacturing decides to take drill bit sharpening seriously. At 5300 RPM, this machine spins faster than most of its competitors - and that's not an accident. Higher speeds mean cleaner cuts on the grinding wheel, which translates to more precise edges on your bits.

The inclusion of both CBN (Cubic Boron Nitride) and SDC (Synthetic Diamond Crystal) wheels tells you something important about the current state of drill bit metallurgy. Modern bits aren't just "steel" anymore. High-speed steel, cobalt-infused alloys, and tungsten carbide all require different grinding media. CBN, which sits just below diamond on the hardness scale, handles HSS bits without generating the heat that would destroy their temper. The SDC wheel tackles the carbide bits that would laugh at a conventional grinding stone.

What's particularly clever about this design is the ER20 collet system - the same precision holding mechanism used in CNC machines. This isn't coincidence. The engineers recognized that the biggest enemy of consistent sharpening isn't the grinding angle or the wheel speed - it's bit slippage. When a bit moves even a fraction of a millimeter during grinding, you get uneven cutting edges. Uneven edges mean the bit walks, drills oval holes, and dulls faster. The ER20 collets eliminate this variable entirely.

The 90° to 140° angle adjustment might seem like overkill until you understand that different materials demand different approach angles. Sheet metal wants a flatter angle to prevent grabbing. Thick steel needs a steeper angle for chip clearance. The ability to dial in the exact angle means the difference between a bit that cuts and one that just rubs.

Drill Doctor 750X: The Workshop Standard

- 3/32" to 3/4" capacity

- 115° to 140° adjustable angles

- Creates and removes split points

- 180 grit diamond wheel included

- Material take-off adjustment

- Can restore broken bits

Drill Doctor emerged from DAREX, an Oregon company that's been obsessing over sharpening geometry since 1973. The 750X represents four decades of refinement, and it shows in the details that matter.

The split point capability deserves special attention. A split point - that distinctive notch at the tip of premium drill bits - reduces the thrust force needed to start a hole by up to 50%. It's the difference between the bit walking across the surface and biting immediately where you place it. Most sharpeners can't create this geometry, and none at this price point can both create and remove it. The 750X can transform a basic bit into a self-centering precision tool, or restore a damaged split-point bit to factory specifications.

But here's the feature that shops love: this machine brings broken bits back from the dead. When a bit breaks, it usually snaps at the flutes, leaving an ugly, unusable stub. The 750X can grind past the break, reestablishing the correct geometry on what remains. Given that larger bits can cost $30 or more, this capability alone justifies the investment for many users.

The diamond wheel that comes standard deserves mention too. At 180 grit, it's fine enough to leave a smooth cutting edge but coarse enough to remove material efficiently. Diamond doesn't load up with metal particles the way aluminum oxide wheels do, meaning more consistent performance over thousands of sharpenings. The wheel that comes with this machine typically lasts 2-3 years in professional use, or essentially forever in a home shop.

The three-step process - align, sharpen, split - seems simple until you understand what's happening mechanically. The alignment port uses a cam system to position the bit at exactly the right presentation angle to the wheel. The sharpening port maintains this angle while allowing rotation. The split port adds that crucial self-centering geometry. Each step builds on the previous one, and the precision is measurable - bits sharpened on the 750X typically match factory specifications within 0.002 inches.

VEVOR MR-20G: Industrial Capacity Meets Precision

- 3-20mm capacity with 18 collets included

- 95° to 135° point angle range

- 4500 RPM operation

- 45# steel construction

- Dual grinding wheels (CBN and SDC)

- 120-watt motor power

VEVOR's MR-20G tells us something about where the drill bit sharpener market is heading. The 20mm maximum capacity pushes into territory that was previously the domain of much more expensive machines. That's a 25/32" bit in imperial measurements - the kind of hole-making capability that serious fabrication requires.

The machine's 45# steel construction (that's a Chinese steel grade roughly equivalent to AISI 1045) represents a significant engineering choice. This isn't pot metal or aluminum casting - it's medium carbon steel that won't flex under load. When you're grinding a 20mm bit, the forces involved are substantial. Any flex in the machine frame translates directly to inconsistency in the grind angle. The VEVOR engineers clearly understood this.

The inclusion of 18 different collets might seem excessive until you consider the precision requirements. Each collet size provides optimal clamping for its specific bit diameter. Using a 10mm collet for a 9mm bit might seem close enough, but that 1mm of play translates to vibration, which becomes heat, which becomes inconsistent geometry. The right collet for the right bit isn't just good practice - it's the difference between a proper sharpening and an expensive mistake.

The adjustable lip relief angle - controllable through positioner pins - addresses a subtle but crucial aspect of drill bit geometry. The lip relief angle determines how aggressively the bit clears chips. Too little relief and the bit binds in the hole. Too much and the cutting edge weakens, prone to chipping. Different materials demand different relief angles, and the ability to adjust this parameter separates serious sharpening equipment from toy-grade alternatives.

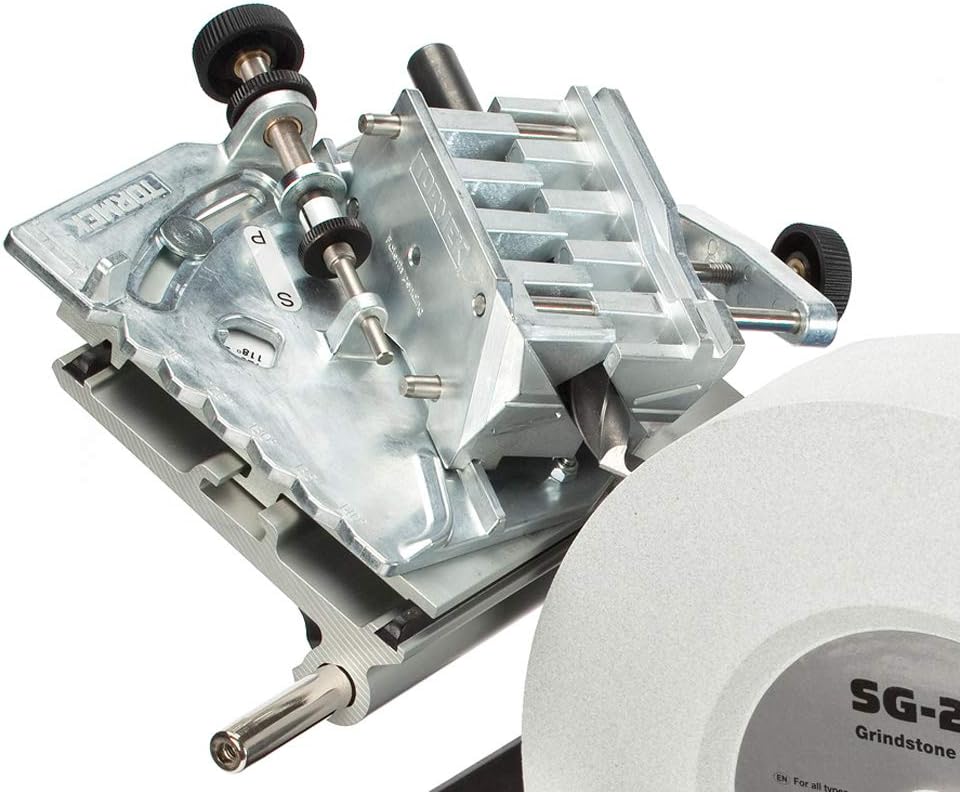

Tormek DBS-22: The Water-Cooled Paradigm

- 3mm to 22mm (1/8" to 7/8") capacity

- 90° to 150° point angle range

- Creates four-facet point geometry

- 7°, 9°, 11°, or 14° clearance angles

- Requires Tormek sharpening system

- Water-cooled grinding process

The Tormek DBS-22 represents a fundamentally different philosophy in drill bit sharpening. This isn't a standalone machine - it's an attachment for Tormek's water-cooled sharpening systems. And that water cooling changes everything.

Heat is the enemy of tool steel. When you grind a drill bit on a conventional high-speed grinder, the temperature at the cutting edge can exceed 400°C in seconds. That's hot enough to draw the temper from the steel, leaving you with a bit that looks sharp but won't hold an edge. Water cooling keeps the temperature below 30°C throughout the sharpening process. The metallurgical structure of the bit remains unchanged. The edge you create is as durable as the day the bit was manufactured.

But the real innovation here is the four-facet point geometry. Look at a factory drill bit under magnification and you'll see two cutting edges meeting at a chisel point. It works, but it's a compromise. The four-facet grind that the DBS-22 creates adds two additional clearance facets behind the cutting edges. This geometry does three things: it reduces the contact area (and thus friction), it improves chip evacuation, and it creates a true point rather than a chisel edge.

Independent testing by the Swedish National Testing and Research Institute found that four-facet ground bits required 25% less thrust force, generated 50% less heat, and lasted up to four times longer than conventional two-facet bits. These aren't marginal improvements - they're paradigm shifts in performance.

The clearance angle adjustability (7°, 9°, 11°, or 14°) might seem like minutiae, but it directly impacts drilling efficiency. A 7° clearance works beautifully in soft materials like aluminum but would burn up in stainless steel. The 14° clearance that stainless demands would cause grabbing and tear-out in plastics. The ability to optimize clearance angle for specific materials transforms a general-purpose bit into a specialized tool.

The Split Point Question

Here's something the manufacturers don't always explain clearly: split points aren't universally better. They excel at starting holes in hard materials without walking. They reduce the thrust force needed to initiate drilling. But in soft materials like brass or thin plastics, a split point can be too aggressive, causing the bit to grab and potentially crack the workpiece.

The Drill Doctor 750X's ability to both create and remove split points becomes valuable in this context. You can customize your bits for specific applications rather than buying separate sets for different materials. A cabinet shop might want conventional points for their wood bits but split points for their hardware installation bits. A metal fabricator might run split points exclusively. The flexibility to modify bits according to actual use patterns represents real utility.

Grinding Wheel Technologies

The evolution from aluminum oxide to CBN and diamond wheels marks a significant technological advancement in sharpening. Aluminum oxide wheels, still common on bench grinders, have a fundamental limitation: they're only marginally harder than the steel they're grinding. This means they wear quickly, load up with metal particles, and generate substantial heat.

CBN (Cubic Boron Nitride) sits at 4,700 on the Knoop hardness scale - second only to diamond. It maintains its cutting ability at temperatures that would destroy diamond, making it ideal for grinding ferrous metals. A CBN wheel can sharpen thousands of HSS bits without significant wear. The consistency of the wheel surface means the 1,000th bit gets the same precision as the first.

SDC (Synthetic Diamond Crystal) wheels, running around 7,000 on the Knoop scale, handle the extremely hard carbide bits that CBN can't touch efficiently. But diamond has an interesting limitation - it reacts chemically with iron at high temperatures, making it unsuitable for steel bits. This is why machines like the ApexscnView and VEVOR include both wheel types. It's not redundancy; it's recognition that modern drill bits span a wide range of metallurgies.

The Precision Factor

When we talk about precision in drill bit sharpening, we're dealing with tolerances measured in thousandths of an inch. A variation of 0.003" in the length of the two cutting edges creates enough imbalance to cause the bit to drill oversize holes. A 2° error in point angle can reduce cutting efficiency by 15%.

This is where the mechanical design of these sharpeners becomes critical. The ApexscnView's ER20 collet system borrows from CNC technology for a reason - it provides repeatable positioning within 0.0005". The Drill Doctor's cam-based alignment system achieves similar precision through purely mechanical means. The VEVOR's 45# steel frame ensures that vibration doesn't introduce variables into the grinding process.

The Tormek takes a different approach, using slow-speed grinding (90 RPM) to eliminate vibration entirely. The trade-off is time - what takes 30 seconds on a high-speed grinder takes 2-3 minutes on the Tormek. But for users who prioritize precision over speed, it's a worthwhile exchange.

Real-World Performance Metrics

Laboratory testing provides one perspective, but field performance tells the complete story. Professional shops using the Drill Doctor 750X report sharpening 30-40 bits per hour once operators are familiar with the process. The same shops estimate that properly sharpened bits last 60-80% as long as new bits, effectively extending the useful life of each bit by 2-3 cycles.

The economics become even more compelling with larger bits. A 3/4" cobalt bit might cost $30-40 new. Sharpening it three times extends its life by 200%, reducing the effective cost per hole by 66%. For shops drilling hundreds of holes per week, the savings accumulate rapidly.

The VEVOR MR-20G's larger capacity pushes these economics further. A 20mm (approximately 3/4") carbide bit can cost $75 or more. The ability to sharpen these larger, more expensive bits in-house transforms them from consumables into durable tools.

The Portability Consideration

The ApexscnView MR-13B's portable design with carry handle addresses a real need in mobile fabrication and field service work. At around 15 pounds, it's light enough to transport but heavy enough to stay stable during operation. Field service technicians report that having sharpening capability on-site eliminates one of the most common causes of job delays.

The Drill Doctor 750X, while technically portable at 6.6 pounds, works best as a dedicated shop tool. The precision of its alignment system benefits from a stable, level surface. Users who mount it to a bench report more consistent results than those who use it as a portable tool.

Maintenance and Longevity

These machines require minimal but important maintenance. The grinding wheels need periodic cleaning to remove built-up metal particles. A wheel dresser or cleaning stone restores the cutting surface and maintains grinding efficiency. The CBN and diamond wheels last significantly longer than traditional wheels - typically 2-3 years in professional use or essentially indefinitely in home shops.

The mechanical components - bearings, motors, adjustment mechanisms - show remarkable durability when properly maintained. The Drill Doctor's 3-year warranty reflects confidence in build quality. Users report machines lasting 10+ years with regular use, making the initial investment even more attractive.

The Professional vs. Hobbyist Divide

The market segmentation in drill bit sharpeners reflects different use patterns and economic considerations. A hobbyist drilling a few holes per month might never recoup the investment in a high-end sharpener. But that same hobbyist might value the satisfaction of maintaining their tools in peak condition, making the investment worthwhile on non-economic grounds.

Professional users face different calculations. Downtime costs, labor rates, and job deadlines create scenarios where having immediate sharpening capability provides value beyond the simple cost of replacement bits. The ability to sharpen a bit in 2 minutes versus driving 20 minutes to a hardware store can determine whether a job stays on schedule.

Future Developments

The drill bit sharpener market shows signs of continued evolution. CNC-controlled sharpening systems, currently limited to industrial applications, may become accessible to smaller shops as costs decline. Automated measurement systems that verify sharpening geometry are already appearing in high-end models.

The integration of different wheel technologies in single machines, as seen in the ApexscnView and VEVOR models, represents a response to the increasing variety of bit materials. As manufacturers develop new alloys and coatings, sharpening technology will need to adapt accordingly.

The Bottom Line

The drill bit sharpener market in 2025 offers solutions across a wide spectrum of needs and budgets. The ApexscnView MR-13B provides professional capability in a portable package. The Drill Doctor 750X delivers workshop-grade precision with the ability to resurrect broken bits. The VEVOR MR-20G handles larger bits that push into industrial territory. The Tormek DBS-22 offers unmatched precision for users already invested in the Tormek ecosystem.

Each represents a different approach to the same fundamental problem: keeping drill bits sharp and productive. The choice between them depends less on which is "best" in absolute terms and more on which aligns with specific use patterns, workshop setups, and economic considerations.

The universal truth across all these machines is that sharp bits work better than dull ones. They cut faster, last longer, produce better holes, and reduce wear on drilling equipment. In an era where replacement costs continue climbing and time efficiency becomes ever more critical, the ability to maintain drill bits at peak performance represents both economic sense and professional competence.

The technology has matured to the point where even entry-level machines deliver results that would have required expensive industrial equipment a decade ago. The question isn't whether to sharpen drill bits - it's which approach makes the most sense for your particular situation.