What PVC Does to Your Saw Blades

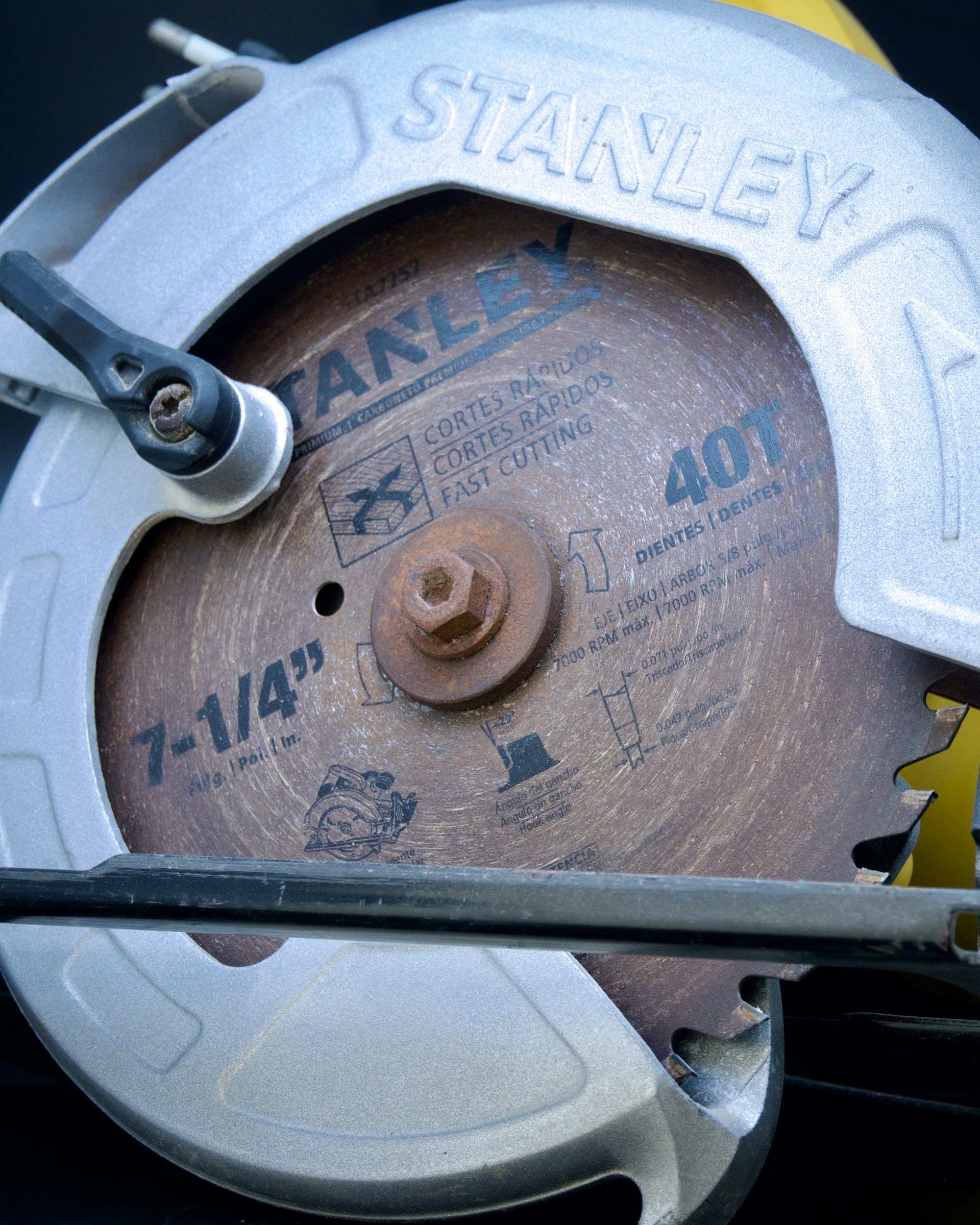

There's a moment of recognition that happens in every workshop where PVC gets cut regularly. You pull the blade off your saw, and instead of the clean teeth you remember, there's this brownish-yellow film coating everything. It's not sawdust. It's not pitch from wood. It's melted plastic that's chemically bonded to your blade.

Here's what blade manufacturers know but rarely advertise: cutting PVC reduces blade life by approximately 40% compared to wood cutting. Not from dulling - the carbide teeth stay sharp. The destruction comes from heat and chemistry that nobody talks about until their expensive blade looks like it was dipped in caramel.

Why PVC Melts Instead of Cuts

PVC behaves unlike any material most saw blades were designed to handle. Wood chips away cleanly. Metal shears off in spirals. But thermoplastic? It turns to taffy when heated. (Similar material conflicts happen with particle board and jigsaws - engineered materials versus tools designed for natural wood.)

The problem starts with basic physics. PVC melts at 212°F, about the temperature of boiling water. Your saw blade spinning at normal speeds generates friction temperatures exceeding 300°F at the cutting edge. Every cut becomes a melting operation where plastic literally fuses to steel.

The friction tells the real story. Wood against steel creates moderate resistance. Melted PVC against steel? Triple the friction. That's why your saw motor bogs down halfway through a 4-inch pipe. Every tooth drags through material that's actively trying to stick to it.

At these temperatures, PVC doesn't just melt - it starts breaking down. The polymer chains decompose, releasing hydrogen chloride gas. Yes, that's hydrochloric acid in vapor form, eating away at your blade while you're trying to make a simple cut.

What's Actually Happening to Your Blade

The deterioration follows a predictable pattern that plays out across thousands of workshop blades:

First, you'll notice slight discoloration on the teeth after a few cuts. The blade still cuts cleanly. This is when most operators think they've figured out the secret. They haven't. The plastic residue is already forming molecular bonds with the blade's surface. (The same false confidence happens when cutting OSB with a circular saw - initial cuts seem fine, then the resin buildup accelerates.)

After 10-20 cuts, problems compound. Each pass adds another microscopic layer of melted PVC. The gullets - those spaces between teeth meant to clear chips - start filling with resolidified plastic. Cutting efficiency drops noticeably. The motor works harder. More heat generates. The cycle accelerates.

Eventually, the blade looks like it went through a candy factory. Brown residue coats everything. But something worse is happening underneath: repeated heating and cooling creates stress fractures in the carbide brazing. The steel body experiences changes from the temperature cycling. Testing shows carbide teeth literally separating from blades after extended PVC cutting - not from impact, but from thermal fatigue. (Though at least PVC's thermal damage is gentler than what Hardie board does to blades - that's pure abrasive destruction.)

How the Industry Solved This Problem

The cutting tool industry recognized this issue and engineered specific solutions. PVC cutting blades aren't marketing gimmicks - they represent genuine materials science adaptations.

Standard wood blades use aggressive tooth angles designed to pull material into the cut. PVC blades reduce these angles dramatically or even reverse them. This prevents the blade from "grabbing" soft plastic and reduces heat generation significantly.

Instead of pointed teeth that concentrate pressure and heat, specialized PVC blades use a chamfered tooth followed by a flat raker. This distributes cutting forces across more surface area, reducing those critical hot spots where melting occurs.

Many PVC-specific blades feature non-stick coatings - Teflon, titanium nitride, or proprietary polymers. These coatings cut the friction dramatically. Laboratory tests show 50% less plastic adhesion on coated blades. The coating eventually wears off, but usually after hundreds of cuts.

The economics make sense once you see the numbers. A standard wood blade cutting PVC might last 200-300 feet of cutting before needing replacement. A dedicated PVC blade in the same application lasts 800-1200 feet. The specialized blade costs slightly more but lasts four times longer.

What Different PVC Types Do to Blades

Not all PVC behaves identically. The formulation dramatically affects how badly your blade suffers. (This material-specific damage pattern mirrors what happens with laminate flooring and miter saws - different formulations create different problems.)

Schedule 40 PVC, the white plumbing pipe everyone knows, causes moderate gumming that's manageable with proper technique. It's rigid enough to cut somewhat cleanly but soft enough to melt and stick.

CPVC, the cream-colored hot water pipe, actually cuts cleaner. Its higher melting point means less gumming at normal blade temperatures. It behaves more like cutting acrylic than standard PVC.

Flexible PVC - the stuff used for pool and spa plumbing - represents the worst-case scenario. Loaded with plasticizers that make it bendy, this material creates extreme gumming. Those plasticizers separate during cutting and create their own contamination layer. That oily film on your blade after cutting flexible PVC? Pure plasticizer that migrated out during heating.

Cleaning Chemistry That Actually Works

When melted PVC bonds to steel, it's not sitting on the surface - it's chemically adhered. Standard blade cleaners don't break these bonds effectively. They might remove surface contamination, but the stubborn yellow film remains.

What actually works involves matching the solvent to the plastic. Acetone aggressively attacks PVC because their chemical properties align. The acetone literally dissolves the plastic film at the molecular level, not just washing it away but chemically disassembling it.

Commercial PVC cleaners typically combine aggressive solvents with penetration enhancers and corrosion inhibitors. They're engineered specifically for this problem. Home shop alternatives that work include pure acetone, citrus-based strippers (the d-limonene attacks PVC effectively), and even oven cleaner in desperate situations.

Temperature accelerates the cleaning reaction. Warming the solvent or blade speeds up the dissolution rate dramatically. Some operators heat blades with heat guns before cleaning, though this risks damaging blade coatings.

What Professional Shops Actually Do

Plumbing contractors who cut PVC daily have developed practices that extend blade life dramatically.

First, they maintain completely separate blades for PVC and never use them for wood. Once a blade cuts PVC, microscopic plastic residue remains even after cleaning. This contamination affects wood cutting quality permanently.

They implement cooling intervals during production cutting. After multiple consecutive cuts, blades cool for a few minutes. This prevents the cumulative heat buildup that causes severe gumming.

Many professionals use cutting lubricants - silicone spray, WD-40, or specialized PVC cutting fluids. These reduce friction and heat generation. The key is moderation: too much lubricant attracts plastic shavings, creating a grinding paste. Too little provides no benefit.

The Market Reality

The cutting tool industry generates billions annually in North America. Specialty plastic cutting blades represent a significant segment - not a niche, but recognition that traditional blades can't handle modern materials.

Major manufacturers now offer dedicated PVC blade lines. Freud's Diablo series includes specific PVC/plastic blades. DeWalt's construction line features non-ferrous/plastic options. Makita offers specialized plastic cutting carbide blades. The price premium runs 20-40% over standard wood blades, but professional users report the investment pays for itself through extended blade life and reduced downtime.

Different User Realities

The average DIYer cuts perhaps 50 feet of PVC annually. At that rate, blade damage remains minimal - annoying but not catastrophic. Clean your blade after each PVC session and accept slightly reduced wood cutting performance.

Contractors cutting PVC weekly face different economics. A dedicated PVC blade becomes standard equipment. The math is straightforward: one specialized blade lasting a year versus multiple destroyed wood blades over the same period.

Industrial operations cutting PVC daily operate in another realm entirely. They maintain blade inventories, implement rotation schedules, and track cutting parameters carefully. When you're cutting thousands of feet monthly, blade optimization directly impacts profitability.

The physics of cutting PVC won't change. Thermoplastics will always melt when heated. The question becomes how you manage this reality. Understanding what's actually happening - the melting, the chemical reactions, the thermal stress - transforms blade destruction from mystery to manageable challenge. The solutions exist in specialized blades, proper techniques, and realistic expectations about what happens when spinning steel meets thermoplastic.