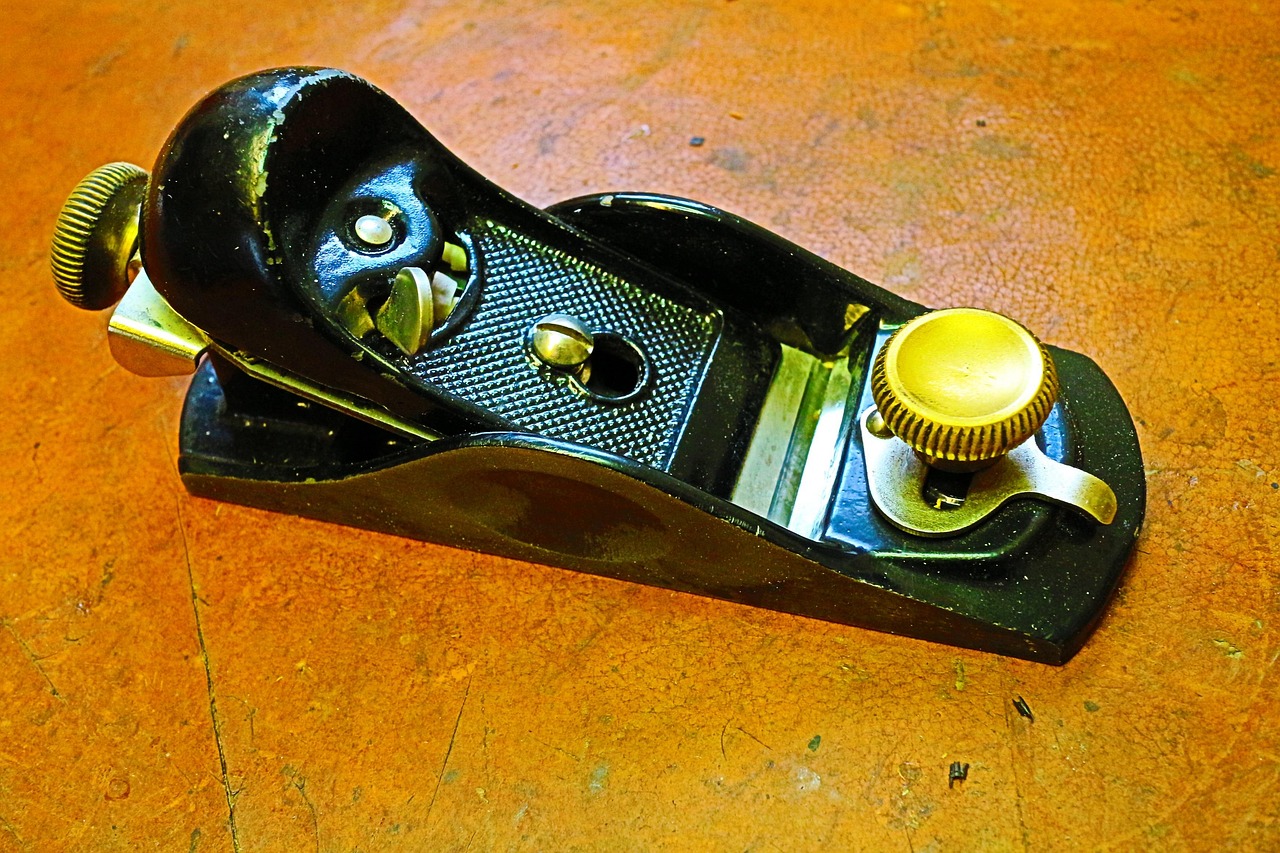

Why Block Planes Work One-Handed

A block plane's 6 to 7-inch length and 1.5 to 2-pound weight create a tool package small enough to grip completely in one hand. The palm wraps around the body with fingers forward, thumb at the side, and the tool's center of mass sitting within the hand's grasp. This compact geometry allows the hand to control both cutting depth pressure and forward motion simultaneously without needing a second hand for balance or guidance.

Contrast this with bench planes at 14 to 22 inches long weighing 5 to 10 pounds. These tools require two hands because no single hand can wrap around enough body length to control them. One hand pushes from the rear handle (tote) while the other guides from the front knob. The block plane's reduced size eliminates this two-point control requirement, consolidating all control functions into a single hand position.

Mass and Control

The 1.5 to 2-pound mass range creates enough weight for momentum to help maintain cutting depth without becoming too heavy for comfortable one-handed work. Lighter planes—under 1 pound—tend to chatter and skip because insufficient mass dampens vibration. Heavier planes—over 2.5 pounds—become tiring to maneuver one-handed for extended periods.

The weight distribution places center of mass roughly mid-body, slightly forward of where most hands naturally grip. This creates slight forward bias that assists the cutting motion. The plane wants to tip forward slightly when held, requiring conscious rear pressure to prevent, but this forward tendency helps maintain forward motion during cuts.

Holding the plane level during cutting requires balancing this forward bias against hand pressure. The technique involves gripping firmly enough to control attitude without squeezing so hard that hand muscles fatigue. The compact size allows small hand position adjustments to shift where pressure applies, making this balance feel natural after brief practice.

Grip Positions

The most common grip wraps the palm around the plane body with the index finger extended forward near the mouth. This position places downward pressure at the cutting zone while the palm drives forward motion. The forward finger provides precise depth control through its proximity to the blade.

Alternative grips place the thumb on top of the plane body with fingers wrapping underneath. This creates a clamping action that some woodworkers find provides better control, particularly when working on assembled pieces where the plane must approach from awkward angles. The top-thumb position works better for pushing than pulling motions.

Side-gripping techniques clamp the plane between thumb on one side and fingers on the other. This grip sees use primarily on shooting boards where the plane travels horizontally rather than across a horizontal surface. The side grip provides control while the plane rides on its side, a situation where top or palm gripping becomes awkward.

The ability to shift between grip positions without stopping work makes block planes versatile. Two-handed bench planes lock users into specific hand positions determined by handle locations. Block planes allow adapting grip to immediate circumstances—a different position for chamfering versus end grain trimming versus spot smoothing.

The Other Hand's Role

While one hand operates the plane, the other hand typically steadies the workpiece. This division of labor proves essential when working on small parts that move under cutting pressure. The non-plane hand clamps the work against bench dogs, in a vise, or against another stable surface.

For edge work on longer boards, the non-plane hand walks along the board, maintaining downward pressure that prevents the board from flexing up into the cutting path. This creates a moving clamp effect where the free hand stays ahead of the plane, bearing down on the section about to be cut.

The free hand also serves as a reference surface for chamfering operations. Running a finger along the edge being chamfered provides tactile feedback about consistency. If the chamfer feels uniform under the finger, it is uniform. This real-time feedback allows immediate correction rather than discovering problems after completing the work.

Some operations require the free hand to support the plane itself. When working on assembled cases where the plane must extend beyond the workpiece edge, the free hand might steady the plane's far end to prevent tipping. This isn't gripping the plane for control, just preventing it from dropping off the work as it completes passes.

Balance and Attitude Control

The compact body allows the hand to sense plane attitude directly. Tipping forward feels immediately obvious through pressure changes on different parts of the hand. The short length means any attitude change creates noticeable pressure shifts, providing instant feedback.

Longer planes require reading attitude through how the tool contacts the work because the hand position sits too far from the cutting zone to feel tip angles directly. A 22-inch jointer plane might tip several degrees before hand position feels different. The 6-inch block plane telegraphs even fractional degree changes immediately.

This sensitivity allows micro-adjustments during cutting. Feeling the plane start to tip forward triggers immediate rear pressure increase to correct. Sensing lack of cutting resistance prompts slight forward pressure to engage the blade more fully. These corrections happen subconsciously once the feel becomes familiar.

The short sole combined with direct attitude sensing makes block planes less forgiving of poor technique than longer planes. A jack plane's 14-inch sole bridges minor technique errors, continuing to cut even if attitude varies slightly. The block plane's short sole follows every attitude change directly, requiring more precise control to maintain consistent cutting.

Work Positioning Flexibility

One-handed operation allows approaching work from positions impossible with two-handed planes. Working on an assembled cabinet with limited access space around the piece often requires reaching across or around obstacles. The block plane fits in the available space and operates in whatever orientation provides access.

Vertical surfaces get planed by holding the work in one hand while planing with the other, both hands working on the same piece simultaneously. Try this with a two-handed plane and you discover you need three hands—two for the plane, one for the work. The block plane's independence from a second support hand makes this work possible.

Overhead planing—working on ceiling trim or the underside of installed components—proves practical with block planes but impractical with bench planes. The light weight and compact size allow reaching up with one hand while the other hand steadies a ladder or provides support. Two-handed planes require both hands on the plane, eliminating any free hand for balance.

These flexible positioning capabilities don't get used constantly, but when specific work demands them, no alternative tool provides equivalent capability. The situations arise frequently enough in furniture making and finish carpentry that the block plane remains indispensable despite power tool availability.

Blade Position and Hand Placement

Block plane blades position roughly mid-sole with some forward bias. This geometry places the blade close to where the index finger naturally extends when gripping the body. The finger proximity allows feeling blade engagement through transmitted vibration and resistance.

Hand position typically sits slightly behind the blade to allow forward finger extension. This creates a slight reach that some woodworkers initially find awkward but proves efficient once habitual. The forward finger pressure right at the cutting zone controls depth more precisely than pressure applied farther from the blade could achieve.

The bevel-up blade orientation means the blade's back faces up, visible during use. This visibility allows monitoring blade condition and adjustment without inverting the plane or removing parts. Quick visual checks confirm blade position and identify damage or dullness immediately.

Force Application Mechanics

One-handed operation concentrates all required force—downward pressure and forward motion—into a single hand position. This demands more from that hand than two-handed operation where force distributes between both hands. The compact size and moderate weight keep demands within comfortable ranges for most users.

Downward force requirements vary with wood density and cutting depth. Light finishing cuts in soft woods need perhaps 2 to 3 pounds of downward pressure. Aggressive cuts in dense hardwoods might require 10 to 12 pounds. The hand must generate sufficient pressure while simultaneously driving forward motion.

Forward force demands range similarly. Light cuts slide forward with minimal resistance. Heavy cuts in dense species create substantial resistance requiring steady pushing. The single hand provides both downward and forward force components, unlike two-handed planes where one hand emphasizes downward pressure and the other provides forward drive.

The combination means hand fatigue accumulates faster with block planes than with two-handed planes when doing equivalent work. The distributed load of bench plane operation proves less tiring for extended sessions. Block planes excel at shorter operations where their convenience outweighs this fatigue factor.

Size Constraints on Work Scale

The 6-inch sole length limits how much surface area the block plane can flatten in single operations. Trying to flatten a 12-inch panel with a 6-inch plane means the sole can't bridge full-panel-scale errors. The plane follows surface variations rather than correcting them, making it unsuitable for serious flattening work.

This limitation matters less for block plane applications since end grain trimming, edge chamfering, and spot smoothing don't require long-scale flatness capability. The work matches the tool's natural capabilities, avoiding situations where sole length constrains results.

The one-handed operation itself doesn't limit work scale—people can plane large surfaces one-handed if the plane could handle it. The size that enables one-handed use creates the limitation. A theoretical 22-inch plane weighing 1.5 pounds might work one-handed but would lack the mass to cut properly. The relationship between size, mass, and controllability creates the practical limits.

Learning Curve Differences

Bench plane technique requires coordinating two hands performing different functions. One hand provides downward pressure at the toe initially, pressure shifts toward the heel at the stroke end, while the other hand drives constant forward motion. Learning this coordination takes practice since the hands must work independently.

Block plane technique consolidates control into one hand, simplifying initial learning. The hand does everything, eliminating coordination challenges between separate hands. New woodworkers often find block planes more immediately accessible than bench planes because of this unified control.

The flip side involves the precision demands of one-handed control. Every hand movement directly affects cutting. There's no second hand to stabilize or correct for the first hand's errors. Small hand position mistakes translate immediately to cutting problems. Bench planes provide more inherent stability through two-point control.

Both techniques become automatic with practice. The initial learning curve favors block planes. Mastery-level control might prove easier to achieve with bench planes because the two-hand coordination provides more control points once coordination becomes automatic.

Blade Adjustment Access

One-handed operation allows adjusting the plane while holding it, maintaining the same grip position before and after adjustment. The adjustment mechanisms—typically a knurled depth knob and a lateral adjustment lever—sit within reach of the holding hand's fingers.

This enables continuous adjustment during work. Feel the blade cutting too heavily, tweak the depth adjustment slightly, resume cutting without releasing the plane or changing position. Bench planes require stopping work, gripping the adjustment knob with the free hand, making changes, then resuming. The interruption breaks workflow more than the block plane's mid-operation adjustment.

The convenience matters most when fitting components where iterative adjustment proves essential. Take a pass, check fit, adjust depth microscopically, take another pass. The block plane allows this iteration without the handling interruptions that slow bench plane adjustment.

Complementing Bench Planes

Block planes don't replace bench planes but handle situations where bench planes prove impractical. The 6-inch length can't flatten panels like a jointer can. The compact size can't smooth large surfaces as efficiently as a smoothing plane. These aren't failings, they're different purposes.

The one-handed capability fills specific roles in the complete types of hand planes toolkit. End grain trimming, edge detailing, spot corrections, and work requiring free-hand positioning all benefit from compact, one-handed operation. These situations arise constantly even in shops emphasizing bench plane work for primary operations.

Most woodworkers eventually own both block planes and bench planes because each serves genuinely distinct purposes. The question isn't which type is better but which type suits the immediate operation. The answer shifts constantly through a typical project, making both essential.

Physical Requirements

One-handed block plane operation demands less overall strength than two-handed bench plane work because the tool weighs less and moves shorter distances. But it concentrates all demands into one hand rather than distributing load between two.

Hand strength and endurance determine how long someone can effectively use block planes continuously. Grip strength matters less than endurance—the ability to maintain moderate grip force for extended periods. Bench plane operation distributes this across both hands, halving the per-hand duration.

People with limited hand strength or arthritis might find block planes more demanding than bench planes despite lower absolute force requirements. The concentration of load into one hand creates issues the distributed load of bench plane use avoids. This represents a significant consideration for tool selection based on individual physical capabilities.

Evolution of Design

Historical block planes evolved from bench planes through progressive size reduction targeting specific applications. Early designs attempted shrinking bench planes proportionally, maintaining two-handed operation patterns. This proved inefficient since the reduced size eliminated the need for two-hand control.

Modern block plane design optimizes for one-handed use through body shaping that fits hands naturally. The rounded sides, lack of handles, and weight distribution all acknowledge single-hand operation rather than trying to miniaturize two-handed controls.

The low-angle versus standard-angle distinction developed alongside size optimization, recognizing that small planes often handle end grain where lower cutting angles excel. The complete design—size, weight, and cutting geometry—targets specific applications rather than trying to be miniature bench planes.

The 6-inch length and 1.5 to 2-pound mass create a tool package allowing complete one-handed control through compact geometry. The consolidated control simplifies some aspects of use while demanding more precision from the operating hand. These characteristics make block planes essential for specific applications involving end grain, detailed work, or situations requiring flexible positioning that two-handed operation can't accommodate. The one-handed capability isn't incidental to block plane design—it's the defining characteristic that determines when and why these planes get used instead of larger alternatives. Understanding what enables this one-handed operation clarifies both the capabilities and limitations that make block planes indispensable tools for specific work while remaining unsuitable for other tasks better handled by two-handed bench planes.