The Best Drill for Concrete Walls In 2026

Listen. Here's what nobody tells you about drilling into concrete: that satisfying moment when a perfectly sharp masonry bit meets virgin concrete at 2,750 beats per minute isn't just construction work - it's applied physics. And the physics, as it turns out, are brutal.

Picture this: You're standing there with your father's old hammer drill, the one he swears by, pressing into a concrete wall with everything you've got. Twenty minutes later, you've made a divot. A suggestion of a hole. Meanwhile, the guy next door punches through the same wall in thirty seconds flat with his SDS rotary hammer. Same concrete. Same determination. Wildly different results.

The difference? About 4.5 joules of impact energy and a fundamental misunderstanding of what concrete actually demands from a tool.

See, concrete doesn't care about your good intentions. It's aggregate held in a matrix of hardened cement paste - essentially manufactured stone with a compressive strength that can exceed 4,000 PSI in residential applications. Understanding drill bit sizes matters here - masonry bits measure slightly larger than their stated size to clear concrete dust during drilling. Your standard drill's clutch mechanism generates maybe 0.5 joules of impact energy. A proper rotary hammer? We're talking 3 to 9 joules, delivered through a pneumatic piston system that would make a jackhammer jealous.

The market knows this. Walk into any tool rental shop and watch what contractors reach for. Not the drill-driver combos. Not even the hammer drills. For concrete leveling work and finishing, you'll need concrete drilling capabilities for anchoring and fastening. They grab the German-engineered SDS systems with impact ratings that read like small explosives specs. There's a reason for that.

The Beautiful Violence of Impact Energy

Here's where things get interesting. Impact energy - measured in joules or foot-pounds - determines whether you're drilling or just heating up concrete through friction. Think of it this way: a standard hammer drill delivers maybe half a joule per impact. It's like knocking on a door. Politely.

An SDS rotary hammer? Different animal entirely.

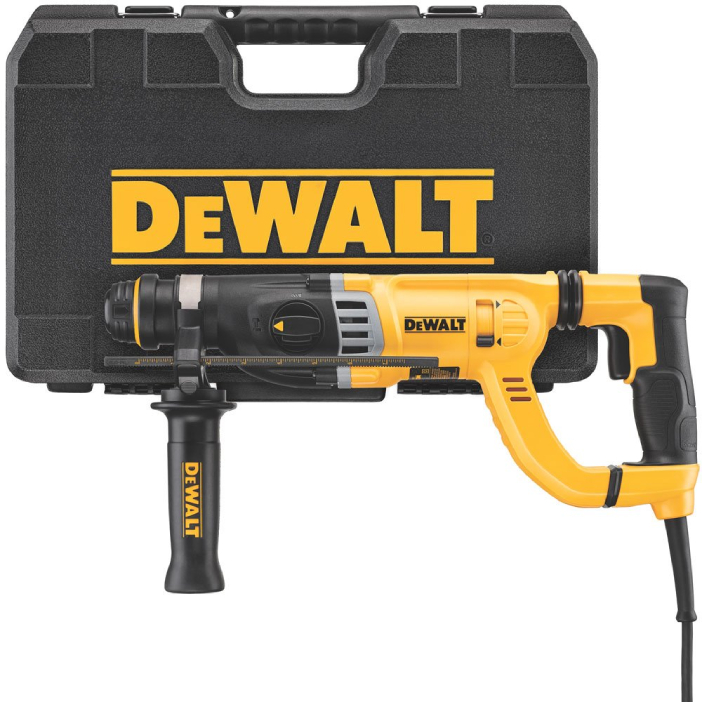

Take something like the DEWALT D25263K. Three joules of impact energy. That's six times the force, delivered through a pneumatic system that operates like a tiny pile driver. The piston compresses air, the air drives the striker, the striker hits the bit. Boom. Boom. Boom. Up to 4,850 times per minute.

The numbers tell you everything. That 8.5-amp motor isn't just spinning - it's driving a mechanical system that converts rotational energy into linear impact force. DeWalt calls their vibration damping system "Active Vibration Control," which sounds like marketing until you realize it's the difference between drilling twenty holes and drilling two before your arms go numb.

But here's what's actually clever: the integral clutch system. Bits bind in concrete. It's not if, it's when. Rebar, aggregate variations, whatever. When that bit stops suddenly, all that rotational energy has to go somewhere. Without a clutch, it goes into your wrists. With one, the tool slips internally, saves your joints, and keeps working. German engineering? More like orthopedic insurance.

When Corded Power Gets Serious

Now we enter SDS MAX territory. Different beast. Different physics.

The Bosch RH540M delivers 6.1 foot-pounds of impact energy. Let me translate that: it's the difference between a firm handshake and getting punched by a middleweight boxer. Every. Single. Impact.

The motor pulls 12 amps at 120 volts. That's 1,440 watts of raw power, but here's the beautiful part - it's variable speed. Dial it down to 170 RPM for precision work or crank it to 340 when you need to make a hole RIGHT NOW. In hammer mode? We're talking up to 2,750 beats per minute. That's not drilling anymore. That's controlled demolition.

At 15.2 pounds, it's got mass. And before you complain about the weight, understand this: mass is your friend here. Newton's third law doesn't take days off. Every action has an equal and opposite reaction, and that weight keeps the bit engaged instead of bouncing around like a caffeinated woodpecker. The tool does the work. You just guide it.

The Vario-Lock system - 12 different chisel positions - sounds like overkill until you're trying to remove concrete around a pipe at 2 PM on a Friday. Suddenly, being able to lock your chisel at exactly the right angle isn't a luxury. It's the difference between going home on time and explaining to your spouse why you're late. Again.

The Cordless Contradiction

Battery-powered concrete drilling shouldn't work. The energy requirements are absurd. You're asking chemical cells to deliver the same punishment that wall current provides effortlessly. It's like asking a marathon runner to sprint the whole race.

Yet here we are.

The DEWALT DCH273B manages 2.1 joules on battery power. That's less than its corded cousin, sure, but it's enough to punch through residential concrete without extension cords snaking across job sites like trip hazards waiting to happen.

The brushless motor is key here. No friction from carbon brushes means less energy wasted as heat. Every amp-hour in that 20V MAX battery gets converted to actual work instead of warming up copper windings. Three operating modes - drill, hammer drill, and chipping - let you match power consumption to the task. Smart, when battery life is measured in minutes, not hours.

At 6.4 pounds, it's manageable for overhead work. That matters more than you'd think. Try holding 15 pounds above your head for ten minutes. Your shoulders will explain the physics better than I can.

Then there's the Bosch GBH18V-45CK24, which shouldn't exist. Nine-point-three foot-pounds of impact energy. From batteries. That's more than many corded tools delivered five years ago.

The catch? It weighs 19.6 pounds with the battery. And those 8.0 Ah battery packs? They're not cheap. But here's the thing about the turbo charging - 50% charge in 15 minutes, 80% in 26. That changes the math entirely. Two batteries, one charger, and you've got near-continuous operation. The Biturbo brushless motor monitors its own power draw, adjusting output to squeeze every possible minute from each charge cycle.

Kickback control isn't just a safety feature here - it's protecting your investment. When a $600 tool binds up, you want it to stop before something expensive breaks. The system monitors rotational resistance constantly, cutting power before physics takes over.

The Beautiful Compromise of Going Small

Sometimes the problem isn't power. It's access.

The Makita XRH06RB gets this. At 10-3/4 inches long and 4.6 pounds, it fits where others can't. Behind water heaters. Inside electrical panels. Those impossible spaces where you need a hole but physics and architecture conspire against you.

Sure, 1.2 joules won't win any power contests. The 680 RPM top speed seems almost leisurely compared to the big boys. But here's what the spec sheet doesn't tell you: when you're wedged into a crawl space trying to drill anchor holes for a pipe hanger, that compact size isn't a compromise. It's salvation.

The two 2.0 Ah batteries make sense here. Higher capacity would just add weight to a tool designed for finesse, not force. It's the surgical scalpel to the SDS MAX's sledgehammer. Different tools for different realities.

The Market Reality Check

Here's what five minutes in any tool rental shop reveals:

| Equipment Category | Impact Energy | Typical Runtime | Weight (with battery) | Market Price Range |

|---|---|---|---|---|

| Standard SDS Corded | 2.5-3.5 joules | Unlimited | 8-12 lbs | $200-400 |

| SDS MAX Corded | 5-8 ft-lbs | Unlimited | 12-18 lbs | $400-700 |

| SDS Battery | 1.5-2.5 joules | 40-80 holes | 5-8 lbs | $250-400 |

| SDS MAX Battery | 6-10 ft-lbs | 20-40 holes | 15-22 lbs | $600-1,200 |

| Sub-Compact Battery | 1-1.5 joules | 60-100 holes | 4-6 lbs | $200-350 |

The rental data tells an even clearer story. SDS corded tools rent for $45-60 per day. Battery versions? $65-85. The premium isn't for the technology - it's for the freedom from extension cords. Contractors will pay 40% more to not deal with cord management. That tells you everything about the real value proposition.

What Physics Teaches Us About Tool Selection

The concrete doesn't care about your brand loyalty. It responds to impact energy, bit quality, and proper technique. Period.

A 3-joule SDS system will drill a 1/2" hole through 4" of concrete in about 30 seconds. Drop to a standard hammer drill's 0.5 joules? You're looking at 3-5 minutes, if the bit survives. Move up to SDS MAX territory with 6+ foot-pounds? Now we're talking 15-second holes and the ability to go bigger - much bigger.

Battery runtime becomes simple math. A 2.1-joule impact drawing from a 5.0 Ah battery at 20V gives you 100 watt-hours of energy. Factor in motor efficiency (around 85% for brushless), impact mechanism losses (another 10%), and you're looking at 40-60 half-inch holes per charge. The Bosch unit with its 8.0 Ah packs? Double that, but at triple the weight.

The compromise always comes back to physics. More power means more weight. Longer runtime means bigger batteries. Cordless freedom means accepting limitations. There's no magic here, just engineering trade-offs measured in joules, amp-hours, and dollars.