The Best Dowel Jig for 2026

There's something almost magical about watching two pieces of wood become one. Not with screws showing on the surface, not with metal brackets breaking up clean lines, but with invisible joints that feel like the wood grew that way. That's what dowel joinery does when it's done right.

The trick isn't in the dowels themselves. Those little cylindrical pieces of hardwood are simple enough. The magic happens in the drilling, in getting those holes positioned so precisely that everything lines up perfectly when you bring the pieces together. Try doing that by hand with just a measuring tape and a steady grip, and you'll understand why dowel jigs exist.

A dowel jig does one thing exceptionally well: it holds your drill bit exactly where it needs to be. The tool clamps onto your workpiece and guides the bit through hardened steel bushings, creating holes that are perfectly perpendicular and, in the case of self-centering jigs, automatically positioned at the center of your stock. No measuring the centerline, no hoping your hand stays steady, no drilling test holes in scrap wood first.

Professional furniture makers have known this for decades. So have serious DIYers who got tired of joints that looked almost right. The difference between a cabinet door that hangs perfectly and one that needs constant adjustment often comes down to those initial dowel holes being off by a millimeter or two.

What separates the dowel jigs worth owning from the ones that end up in the back of a drawer comes down to a few key factors. Self-centering mechanisms save enormous amounts of setup time. Hardened steel bushings last through hundreds of projects instead of wearing oval after a dozen uses. Adjustable capacity means you can work with everything from thin drawer fronts to thick table legs without switching tools. And solid construction matters because any flex or play in the jig translates directly to misaligned holes in your work.

The jigs we're looking at here represent different approaches to the same fundamental challenge. Some prioritize maximum capacity for working with larger stock. Others focus on portability and quick setup. A few stick with proven designs that haven't needed updating in seventy years. All of them are self-centering, because once you've used that feature, going back to manual centering feels like using a sundial to tell time.

The basic principle is straightforward enough. A dowel jig clamps onto your workpiece and positions hardened steel bushings exactly where you need to drill. The bushings guide your bit perpendicular to the surface, preventing the angled holes that plague freehand drilling. But the real innovation that separates modern jigs from their ancestors is self-centering.

Traditional dowel jigs required you to measure and mark the centerline of your stock, then carefully position the jig on that line. Self-centering jigs eliminate that entire process. When you tighten the clamp, opposing jaws move inward equally from both sides, automatically positioning the drill guides at the exact center regardless of your stock thickness. It's the difference between a five-minute setup and a thirty-second one.

The size options matter more than you might think. Most dowel work uses 1/4-inch, 5/16-inch, or 3/8-inch dowels, which handle the majority of furniture and cabinet projects. Larger 7/16-inch and 1/2-inch dowels come into play for heavier construction or thicker stock where you need more glue surface area and stronger joints. Having all these options in one jig means you're not hunting through your tool cabinet trying to remember which jig works with which dowel size.

Capacity determines what you can actually build. A jig limited to 2-inch stock works fine for drawer fronts and cabinet doors but stops you cold when you want to join table legs or thick workbench components. Wide-capacity jigs open up more ambitious projects, though they tend to be heavier and more expensive. The question becomes whether you're building furniture or just doing repairs and small projects.

The Milescraft Kit: Everything in One Package

- Handheld self-centering jig with adjustable fence

- Three hardened steel bushings (1/4", 5/16", 3/8")

- Includes brad point drill bits, depth stops, dowel centers, and wood glue

- Works with stock from 1/2" to 1-1/2" thick

There's something to be said for opening a box and finding everything you need to start working immediately. The Milescraft 1333 takes that approach, bundling the jig itself with all the bits, stops, and accessories that would otherwise require separate trips to the hardware store.

The jig operates handheld, which means you're holding it against your workpiece with one hand while drilling with the other. This sounds awkward until you actually try it, at which point the speed becomes obvious. No clamping, no setup, just position and drill. The self-centering pins automatically find center on your stock, and the adjustable fence lets you set precise spacing from the edge for multiple dowel holes.

The three hardened steel bushings cover the most common dowel sizes, and having brad point drill bits included means you're not trying to figure out which bits work best for dowel holes. Brad points are specifically designed for this, with a sharp center spur that prevents walking and clean cutting edges that leave smooth holes. The depth stops attach to each bit, ensuring you don't drill too deep and punch through the other side of your work.

Dowel centers solve one of doweling's trickier problems. After drilling holes in one piece, you need to mark exactly where the corresponding holes go in the mating piece. Dowel centers insert into your first set of holes, their pointed tips protruding just enough to mark the second piece when you press them together. It's more reliable than measuring and definitely faster.

The kit works with stock from 1/2-inch to 1-1/2-inch thick, which covers most furniture work but stops short of heavy timber construction. Board width matters here too, with minimums of 2 inches for the smaller bushings and 3-1/4 inches for the 3/8-inch option. These limitations come from the jig's physical size and how the self-centering mechanism positions on the workpiece.

The carrying case keeps everything organized, which matters more than it sounds like it should. Dowel jigs accumulate accessories, and searching for the right bushing or depth stop in a drawer full of tools wastes the time the jig is supposed to save you.

Check the current price on Amazon.

The Standalone Milescraft: Just the Jig

- Same handheld design and self-centering mechanism

- Three metal bushings with removable adjustable fence

- No additional accessories included

- 1/2" to 1-1/2" stock capacity

If you already own decent drill bits and don't need the full kit, the 1332 offers the same jig without the extras. It's the same handheld design with the same metal bushings and self-centering pins, just without the carrying case full of accessories.

This makes sense for woodworkers who've accumulated tools over time and have brad point bits, depth stops, and marking methods they prefer. The jig itself works identically to the kit version, handling corner joints, edge joints, and surface joints with the same one-handed positioning approach.

The removable fence adjusts for different setback distances from your workpiece edge, letting you position multiple dowels in consistent rows. This matters when you're joining wider boards or need dowels spaced at specific intervals for strength and appearance. Without the fence, the jig still centers itself on stock edges for basic joints.

The same capacity limitations apply: 1/2-inch to 1-1/2-inch thick stock, with board width minimums matching the kit version. The metal bushings are identical, providing the same guidance and durability through repeated drilling operations.

The price difference between this and the kit version often comes down to whether you value having everything in one package versus saving a bit by buying only what you need. If you're setting up a workshop from scratch, the kit makes more sense. If you're adding to an existing tool collection, the standalone jig might be all you need.

Check the current price on Amazon.

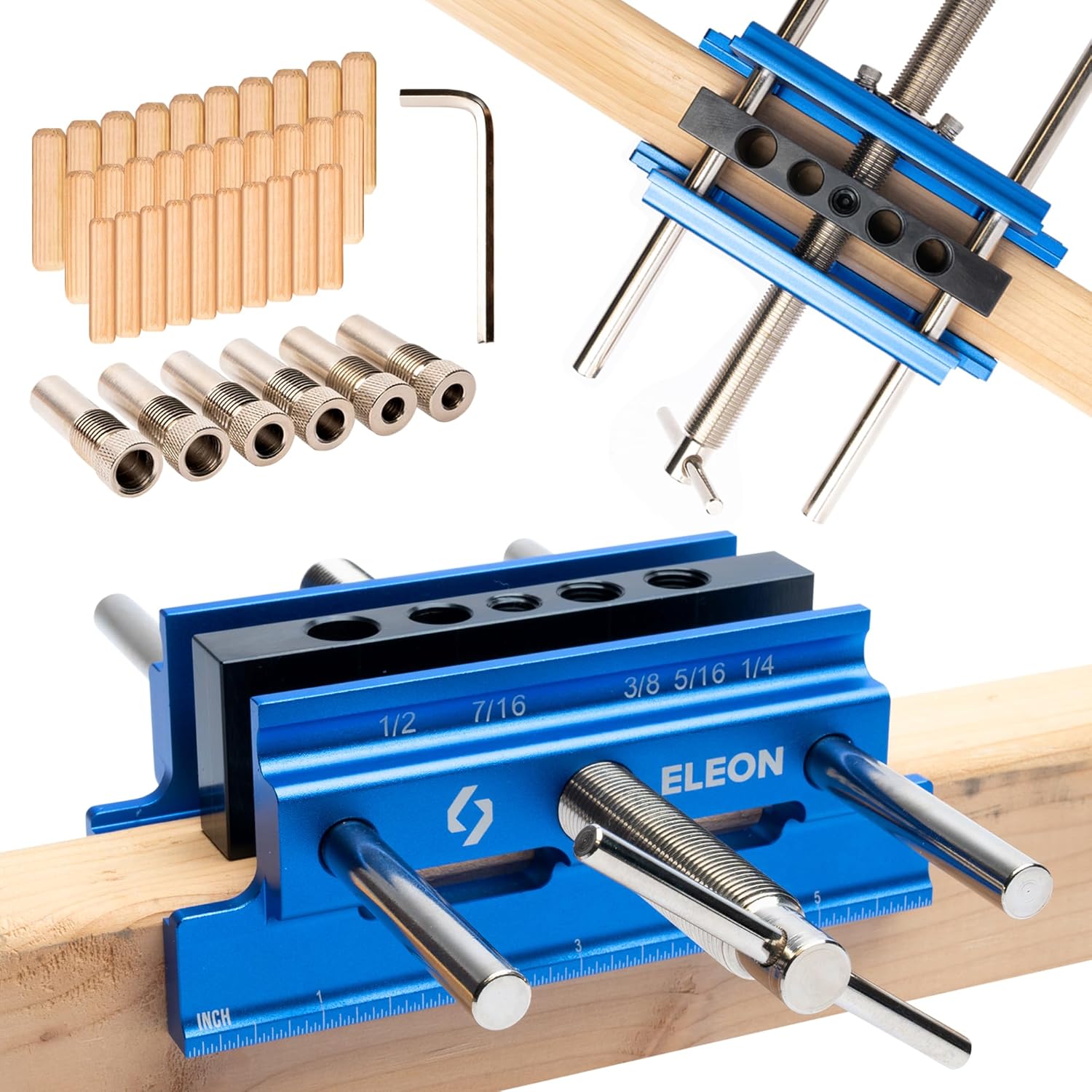

The Eleon: Extra Capacity and Grip

Eleon Self-Centering Dowel Jig

- Aluminum alloy construction with elongated clamping jaws

- Extra-large clamping opening for varied stock sizes

- Built-in ruler markings for quick dowel spacing measurements

- Includes starter dowels

The Eleon takes a different approach to the capacity question. Instead of the handheld style, this jig clamps directly onto your workpiece with an extra-large opening that accommodates a wider range of stock dimensions. The elongated jaws distinguish it from competitors that use narrower side clamps.

Those longer jaws create more contact surface with your workpiece, and the grip pattern molded into them increases friction to prevent slipping during drilling. This matters because any movement of the jig while the bit is in the wood creates oval holes instead of round ones, throwing off your entire joint alignment.

The aluminum alloy construction keeps weight reasonable at 1.63 kilograms while providing the rigidity needed to resist flexing under clamping pressure. Cheaper jigs sometimes use thinner materials that can bend slightly when tightened, which again translates directly to positioning errors in your holes.

Built-in ruler markings run along the jig's body, giving you quick reference points for spacing multiple dowels. Instead of measuring and marking each position separately, you can set your first hole, then use the ruler to position subsequent holes at consistent intervals. This speeds up projects like face frames or door panels where you need several dowels in a row.

The package includes starter dowels, which seems minor until you're ready to test your setup and realize you need to make a store run before you can actually drill anything. Having them on hand means you can verify your joint fit immediately and make adjustments if needed.

The extra-large opening and elongated jaws make this jig suitable for thicker stock and irregular shapes that handheld jigs struggle with. When you're working with chunky table legs or curved chair components, having solid clamping across a longer surface area keeps everything stable through the drilling process.

Check the current price on Amazon.

The Woodstock: Solid Mid-Range Design

- Aluminum body with hardened steel bushings

- Five drill guide options (1/4", 5/16", 3/8", 7/16", 1/2")

- Handles stock up to 2" thick

- Dual bushing capability for parallel holes

The Woodstock D4116 sits in that middle ground between handheld convenience and heavy-duty capacity. It's a traditional vise-style jig where you clamp onto your workpiece using a threaded screw mechanism, positioning the drill guides exactly where you need them.

The aluminum casing integrates the vise plates and clamping mechanism into one solid unit, with engraved markings showing each drill size. Between the clamping plates sits the drill guide section with five options: three threaded guides at 1/4-inch, 5/16-inch, and 3/8-inch, plus two non-threaded guides at 7/16-inch and 1/2-inch.

The threaded guides accept hardened steel bushings, and the jig comes with two of each size for the three smaller measurements. This dual-bushing setup lets you drill two parallel holes without repositioning the jig, which saves considerable time on projects requiring multiple dowels per joint. Install two 3/8-inch bushings, drill both holes, move to the next position.

The 2.51-pound weight gives the jig enough mass to stay stable during drilling without becoming cumbersome to move around your work. It handles stock up to 2 inches thick, covering most cabinet and furniture work but stopping short of heavy timber projects. Circular or irregularly shaped stock works fine since the self-centering mechanism adjusts to whatever you clamp between the jaws.

Maintenance requires minimal effort. Periodically brush away sawdust from the vise screw threads and drill guide threads, then apply a thin coat of light machine oil. This keeps the threads moving smoothly and prevents rust on the steel components. That's essentially the entire maintenance routine.

The hardened steel bushings resist wear better than softer metals, maintaining their shape and size through hundreds of holes. When bushings start to wear oval instead of staying round, they produce oval holes in your work. Quality bushings postpone that degradation significantly, making the initial investment worthwhile for anyone planning regular use.

Check the current price on Amazon.

The Dowl-It 1000: Unchanged Since 1949

Dowl-It 1000 Self-Centering Doweling Jig

- Made by Rockler in the US since 1949

- Six drill guide sizes including 3/16"

- Aluminum construction with hardened steel center block

- 2" stock capacity, 2.35 pounds

Some tools get redesigned every few years as manufacturers chase improvements or cost reductions. The Dowl-It 1000 has remained essentially unchanged since Rockler introduced it in 1949, which tells you something about the original design's effectiveness.

At first glance it resembles the Woodstock D4116, sharing that same aluminum body with integrated vise mechanism and clamping plates. The weight is similar at 2.35 pounds, and the 2-inch stock capacity matches as well. Both handle standard rectangular stock and irregular shapes equally well through their self-centering operation.

The distinguishing feature sits in that center drill guide block. Where most jigs offer five hole sizes, the Dowl-It 1000 provides six: 3/16-inch, 1/4-inch, 5/16-inch, 3/8-inch, 7/16-inch, and 1/2-inch. That additional 3/16-inch option opens up smaller-scale work that other jigs can't handle as precisely.

The hardened steel center section contains all six sizes as permanent guides rather than using removable bushings. This eliminates the bushing management that comes with other jigs but means you're limited to these specific sizes. For most woodworkers, these six cover every practical need, and the absence of bushings to lose or wear out simplifies long-term ownership.

You drill directly through the steel guides using the appropriate sized bit. No threading bushings in and out, no wondering if you have the right size bushing in your tool box. Just select the hole that matches your dowel diameter and drill.

The self-centering mechanism works identically to other vise-style jigs. Tighten the screw and both jaws move inward equally, automatically positioning the drill guides at center regardless of your stock thickness. It's the same time-saving feature that makes self-centering jigs worth the investment over manual-positioning designs.

Rockler's continued US manufacturing speaks to a commitment to the original quality standards. The design hasn't needed updating because it solved the core problem effectively from the beginning: guide a drill bit perpendicular through the center of stock at common dowel sizes. Seventy-plus years later, that's still exactly what dowel jigs need to do.

Check the current price on Amazon.

Choosing Based on What You Actually Build

The handheld Milescraft designs make sense when speed and portability matter more than maximum capacity. If you're working on site, building cabinets in a customer's home, or doing repairs where hauling heavy tools around becomes tedious, the one-handed operation and minimal setup pay off immediately. The kit version suits beginners who need everything to get started, while the standalone jig works for experienced woodworkers with their preferred bits and accessories already on hand.

The Eleon's extra clamping capacity and elongated jaws address different needs. When your projects regularly involve thicker stock or unusually shaped pieces, that wider opening and improved grip prevent the frustration of trying to make a smaller jig work with material it wasn't designed for. The built-in ruler markings particularly benefit production work where you're making multiple identical pieces.

Traditional vise-style jigs like the Woodstock D4116 offer a middle path between handheld convenience and maximum capacity. The dual-bushing capability speeds up projects requiring multiple dowels per joint, and the 2-inch capacity handles most furniture and cabinet work. It's heavier than handheld options but still portable enough for different work areas.

The Dowl-It 1000's six hole sizes, including that unusual 3/16-inch option, make it valuable for varied work that might include smaller-scale projects like jewelry boxes or toy construction alongside standard furniture. The permanent steel guides eliminate bushing management, which some woodworkers prefer even if it limits size options. The unchanged-since-1949 design appeals to those who value proven reliability over modern innovations.

Stock thickness determines capacity requirements. If you rarely work with material over 1-1/2 inches thick, the handheld Milescraft jigs provide adequate range with superior convenience. Projects involving 2-inch stock push toward the Woodstock or Dowl-It designs. Anything thicker than 2 inches requires specialized high-capacity jigs that move into different price ranges entirely.

The frequency of use matters too. Occasional dowel work for small repairs or hobby projects doesn't justify expensive jigs with features you won't use. Regular furniture building or professional cabinet making demands durability and capacity that cheap jigs can't provide. Match the tool to your actual project volume rather than buying capability you'll never need or skimping on quality for work that demands precision.

Getting Joints That Actually Fit

Even the best dowel jig produces poor results if you rush the setup. The self-centering feature eliminates one variable but doesn't compensate for sloppy work in other areas. Your drill bit needs to be sharp and properly sized for your dowels. Dull bits create rough holes that don't glue well, and oversized holes produce weak joints with gaps.

Clamping pressure should be firm but not excessive. Overtightening can flex thinner stock or even crack it, throwing off your alignment. The goal is stability during drilling, not maximum possible clamping force. The workpiece shouldn't shift when you apply drill pressure, but you shouldn't see visible deformation either.

Drilling speed affects hole quality more than most people realize. Too fast generates excessive heat that can scorch the wood and dull your bit prematurely. Too slow bogs down the bit and creates rough walls inside the hole. Brad point bits work best at moderate speeds, letting the cutting edges do their work without forcing.

Depth consistency matters for joint strength. Drilling too shallow leaves insufficient glue surface area. Drilling too deep risks punching through the opposite face. Depth stops solve this problem if you use them, but they need proper adjustment for each stock thickness and dowel length combination.

The dowels themselves contribute to joint quality as much as the holes. Slightly oversized dowels create friction-fit joints that hold even before glue, but require more drilling force and risk splitting thin stock. Loose dowels assemble easily but depend entirely on glue for strength. Most woodworking dowels are sized for light interference fit, providing some friction while still allowing reasonable assembly. Understanding drill bit sizes helps you match bits precisely to your dowel diameters.

Glue application determines how well your careful drilling translates to actual joint strength. Too little glue creates starved joints that fail under stress. Too much glue creates hydraulic pressure that can split wood or prevent full seating of the joint. Apply glue to both the dowels and the holes, using enough to coat all surfaces without excess pooling at the bottom of blind holes.

Test fits before gluing save considerable frustration. Dry-assemble your joint to verify alignment and fit. If dowels resist insertion excessively, light sanding resolves the problem more easily than trying to force assembly after glue application. If joints feel loose, undersized dowels or oversized holes require addressing before permanent assembly.

Why Traditional Joinery Still Matters

Dowel joints disappeared from high-end furniture manufacturing decades ago, replaced by domino joinery systems and automated equipment that cut precise mortise-and-tenon joints faster than human hands could mark centerlines. Production woodworking moved on to methods that better suit factory efficiency and computer-controlled equipment.

But small-scale furniture making and custom cabinet work still benefit from dowel joinery's simplicity and effectiveness. The joints are strong enough for furniture that experiences normal use. The equipment costs hundreds instead of thousands. The learning curve measures in hours rather than months. For individual craftspeople and small shops, those advantages outweigh the superior strength of more complex joints that require more complex tools.

The invisibility of dowel joints appeals to designs that emphasize clean lines and uninterrupted wood grain. Exposed mortise-and-tenon joints can be beautiful when that aesthetic suits the piece, but sometimes you want nothing visible except wood meeting wood. Dowels provide that while maintaining structural integrity adequate for most furniture applications.

Repairs particularly benefit from dowel joinery. Fixing a broken chair rung or reinforcing a wobbly table leg often requires working in confined spaces where router jigs or domino machines can't operate effectively. A dowel jig clamps onto the broken piece, guides your holes true, and lets you create a repair joint that often ends up stronger than the original construction.

The skill development path matters too. Learning dowel joinery teaches fundamental concepts about wood movement, grain direction, and joint strength that apply to more advanced techniques. Starting with dowels builds understanding of why joints fail and what makes them strong, knowledge that transfers directly to mortise-and-tenon work, dovetails, and other traditional joinery methods. If you're serious about woodworking, mastering dowel joints provides a solid foundation for everything that follows.

The Invisible Connection

Two pieces of wood, brought together with nothing visible holding them. No hardware, no exposed fasteners, just grain meeting grain as if they'd always been one piece. That's the appeal of dowel joinery, and it's why woodworkers keep coming back to it despite all the modern alternatives.

The jigs themselves are simple tools. Clamps, bushings, and self-centering mechanisms that do one job exceptionally well. But that simplicity is the point. Sometimes the best tool for the job is the one that gets out of your way and lets you focus on the work itself.